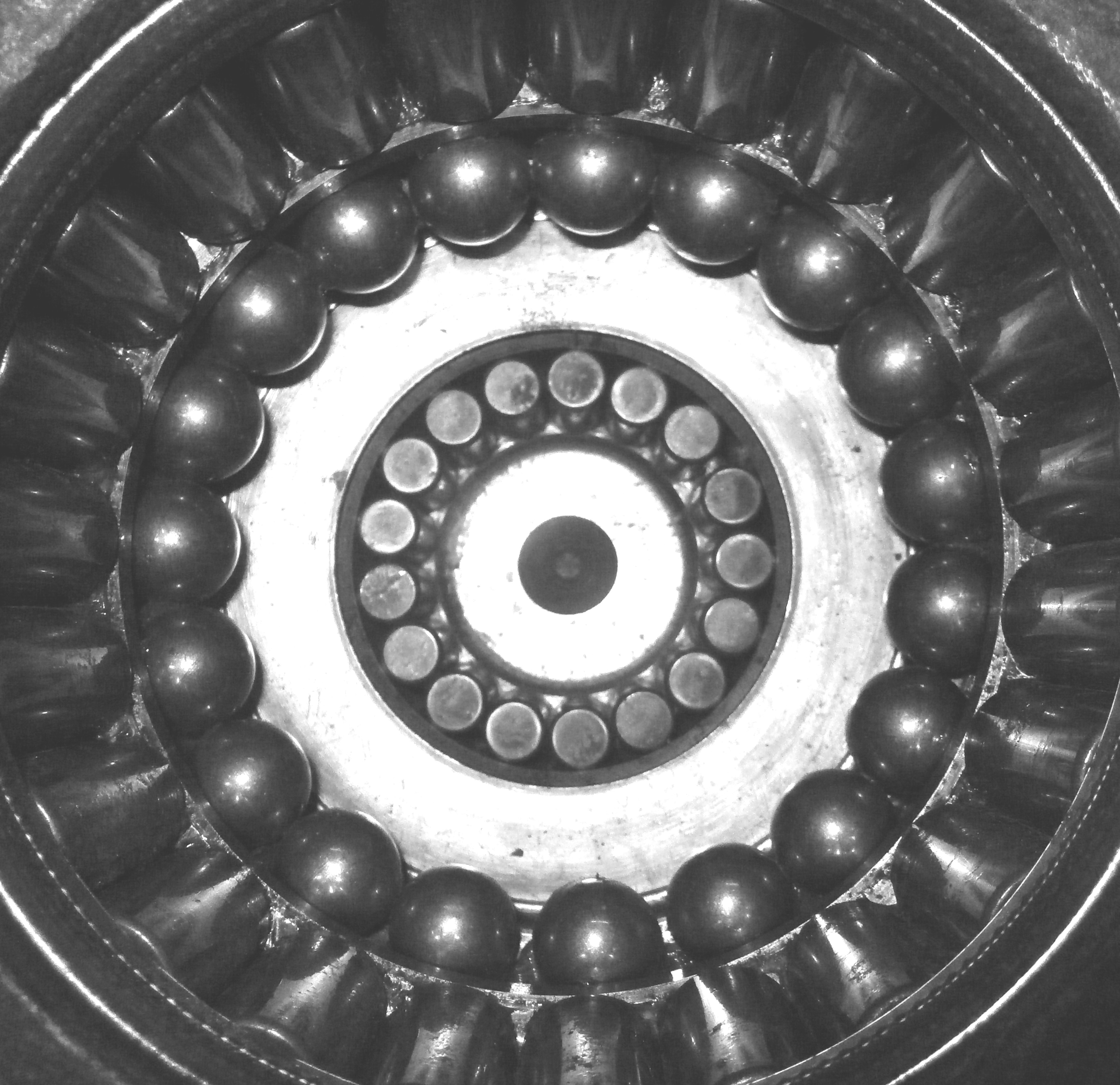

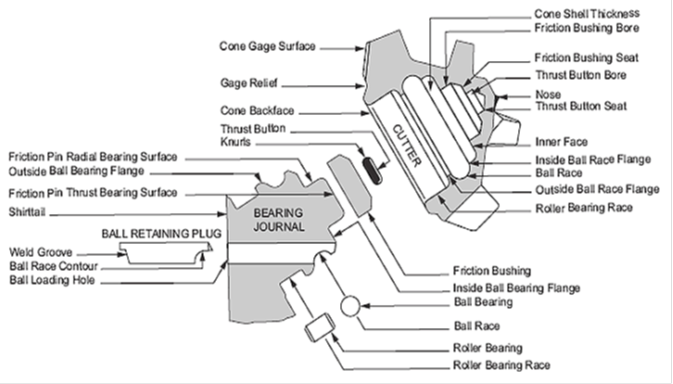

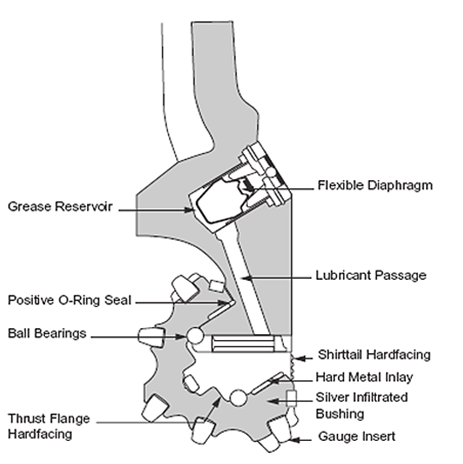

With the largest bit refurbishment and maintenance facility in the UK, Tricore offers inspection, repair and refurbishment service for both roller cone drill bits and hole openers. After initial inspection an evaluation report is given on the bearings, teeth, gauge and seal effectiveness. The bit or hole opener cutter is assessed for refurbishment and further use. Service, repairs and refurbishment include, de-rusting, IADC dull grading, connection inspection, remove compensator and inspect diaphragm and grease for contamination. The teeth are rebuilt and the shirttail hard facing repaired as required. The bearings and cones are greased with customer supplied or recommended lubricant. Stringent procedures and processes are followed to ensure only the highest quality product is delivered to our customers.

Tearing down roller cone bits is a time consuming and often under utilized tool. At Tricore we are able to offer this service to our customers to give a better visibility of a bits performance. Detailed examination of the bit allows for greater understanding of how the bit failed or how much life is left in the tool.

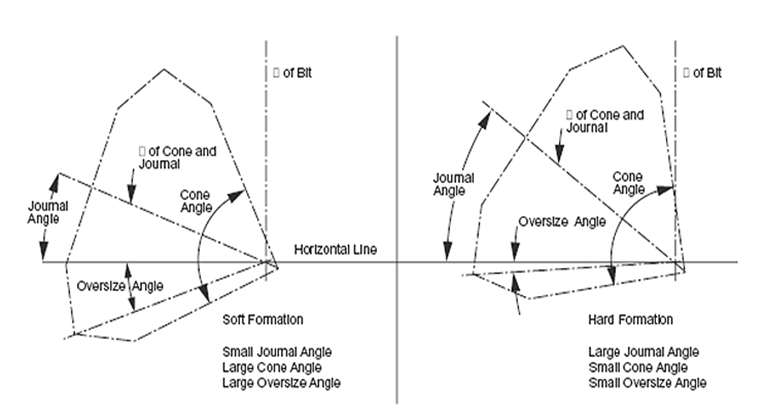

Tricore are able to offer training on roller cone drill bits to small groups of drilling engineers or drill bit engineers. This is a practical course where trainees are shown the inner working of a mill tooth and TCI, sealed and non sealed roller cone drill bits and their component parts. We can modify the training to meet your requirements and the needs of the students.